Modern inspection work has become faster and more accurate thanks to advanced tools. One of the most useful tools in this category is the inspection camera.

Whether you are a plumber checking pipes, an auto mechanic looking inside engines, or a DIY enthusiast exploring hidden corners of your home, an inspection camera provides clarity, efficiency, and precision.

In this article, we’ll explore what an inspection camera is, its different models, applications, features, benefits, and how to choose the right one for your needs.

What is an Inspection Camera?

An inspection camera (also called a borescope or endoscope) is a device designed to look into spaces that are otherwise inaccessible. It typically consists of:

A flexible or rigid cable

A tiny camera lens at the end

LED lights for illumination

A screen or smartphone connection for real-time viewing

These cameras are built to handle tough environments.

Types of Inspection Cameras

1. Rigid Inspection Cameras

Durable and stable but limited in flexibility.

2. Flexible Inspection Cameras

Equipped with a bendable cable, ideal for plumbing and automotive inspections.

3. Wireless / Wi-Fi Inspection Cameras

These cameras offer wireless convenience.

4. USB Inspection Cameras

Plug directly into a laptop or PC for live feed inspections.

5. Dual-Lens Inspection Cameras

Feature enhanced visibility for complex inspections.

Key Features to Look For

When buying an inspection camera, consider:

Resolution: High-quality video.

Cable Length: From short household use to long industrial inspections.

Lighting: Adjustable LED lights for dark environments.

Waterproof Rating: IP67+ for wet or dirty environments.

Compatibility: Works with Android/iOS devices.

Recording Options: Real-time saving for documentation.

Applications of Inspection Cameras

1. Plumbing

Inspection cameras make pipe repairs easier.

2. Automotive

Mechanics use them to check Inspection camera engine cylinders.

3. Home Maintenance

DIY users can inspect air ducts.

4. Industrial Maintenance

Factories use inspection cameras for machine diagnostics.

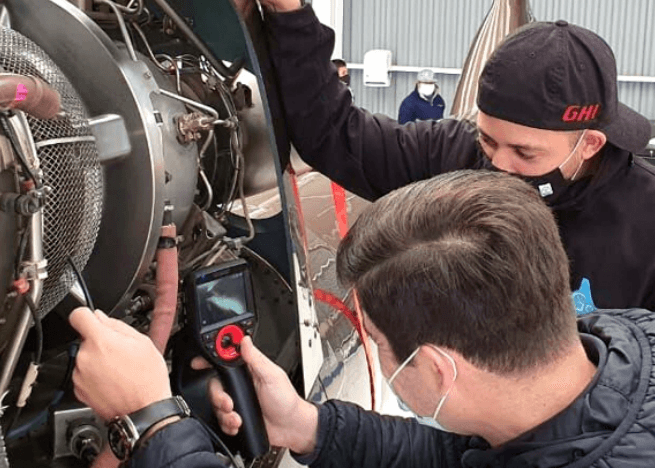

5. Aerospace and Defense

Used to detect micro-damages in complex machinery.

6. Medical Field (Specialized Endoscopes)

While not the same as household tools, similar technology is used in medical imaging.

Benefits of Using an Inspection Camera

Accessibility: Access areas without dismantling equipment.

Time-Saving: Reduces unnecessary repairs.

Cost-Efficiency: Extends equipment life.

Accuracy: Provides real-time clear visuals.

Versatility: Works for both professionals and DIY.

How to Choose the Best Inspection Camera

Define Your Use Case – Plumbing vs automotive vs industrial.

Check Cable Length & Flexibility – Shorter for compact inspections.

Consider Image Quality – Better clarity for detailed inspections.

Select Waterproof & Durable Models – Shockproof casing.

Evaluate Budget & Brand – Check reviews and reliability.

Future Trends in Inspection Cameras

AI-powered Image Analysis for automatic defect detection.

Augmented Reality (AR) Integration for improved visualization.

Ultra-thin & Nano Cameras for medical and microelectronics.

5G & Cloud Connectivity for remote inspection in real-time.

Conclusion

The inspection camera is no longer just a tool—it is a game-changer for professionals and DIY enthusiasts alike. From plumbing and automotive repair to industrial maintenance and aerospace safety, these devices offer a simple yet powerful way to inspect hidden areas.

If you are looking for a way to simplify complex inspections, investing in a high-quality inspection camera is a smart move.